Insulation Contractor

Thermal, Acoustic & Cryogenic Insulation Specialists

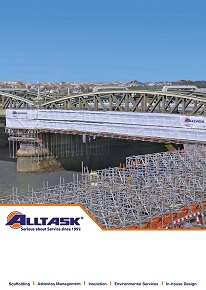

Alltask Insulation is a trusted UK insulation contractor with extensive experience delivering high-quality insulation solutions across a wide range of industrial and commercial insulation projects.

As a fully accredited insulation company, we design, specify, and install comprehensive insulation systems including thermal insulation, acoustic insulation, and cryogenic insulation. Our expert insulation services help reduce energy costs, improve process efficiency, enhance workplace safety, and lower CO₂ emissions.

Comprehensive Insulation Solutions

At Alltask Insulation, a leading UK insulation company, we deliver expert insulation services tailored to meet the demands of any insulation project — from small-bore pipework to large-scale industrial structures. Whether you require thermal insulation, cryogenic insulation, or acoustic insulation services, our experienced team provides reliable and cost-effective insulation solutions.

Our full range of insulation services includes the protection of pipework, fittings, ductwork, boilers, vessels, and storage tanks across high-temperature and low-temperature environments, helping to optimise energy efficiency and ensure regulatory compliance.

Expert Insulation Services with a Focus on Personnel Protection

Putting Safety First

As a trusted UK insulation contractor, Alltask Insulation services specialises in designing, specifying, and installing effective personnel protection systems to reduce the risk of burn injuries or electric shock caused by contact with hot or cold surfaces.

With health and safety at the core of our operations, our fully equipped insulation workshop manufactures high-quality insulation cladding for pipework, ductwork, bends, valve covers, and boxes — all fabricated to the highest industry insulation safety standards. As a full-service insulation company, we also produce custom-made insulation mats and insulation blankets sewn in-house for precise fit and performance.

Our responsive insulation services range from 24-hour emergency call-outs to large-scale outages, including term maintenance and shutdown support for planned or unplanned insulation projects.

Please read our brochure for an overview of the insulation services offered by Alltask. If you would like to be sent a hard copy please complete a contact form.

Talk to us about insulation

When you’re looking for insulation services and an insulation company you can rely on, whatever the size, nature, or type of your insulation project, we can help. Talk to us today so we can find out more about your insulation project and what we can do to help. We look forward to hearing from you.